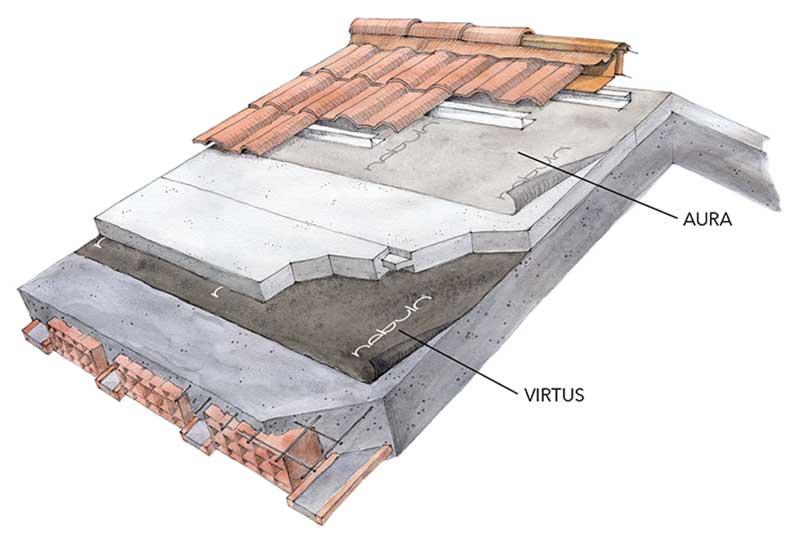

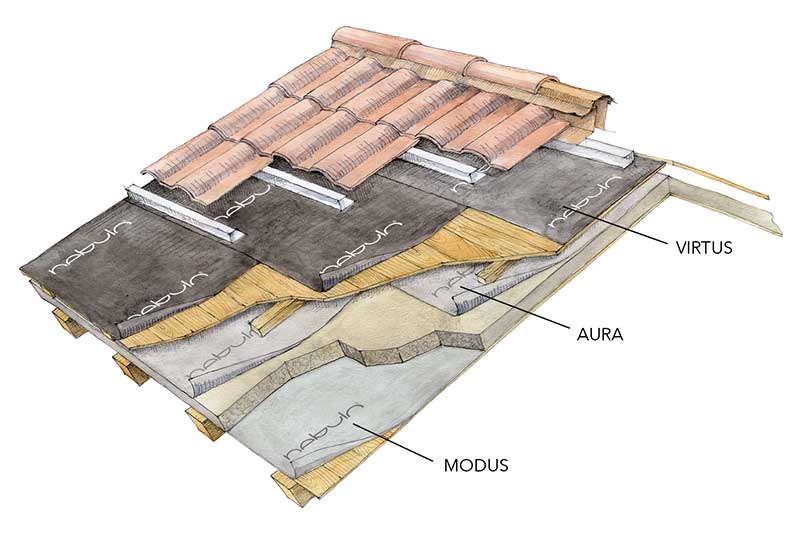

AURA: BREATHABLE UNDERLAY

Breathable underlay in multilayer polypropylene

Allows excess moisture to rapidly escape

AURA consists of three layers of polypropylene bonded by means of an ultrasonic process without the use of any additive or solvent, in total respect for the environment.

Applied to wooden roofs on top of the insulation, this underlay allows excess moisture to rapidly escape while maintaining the thermal performance of the insulation intact.

Completely Made in Italy. Produced with ultrasound technology. Possesses high mechanical performance, non-slip properties and is fully recyclable.

- Available in 135, 150, 180 and 220 g/m2 versions.

COMPOSITION

Top layer: heavy non-woven polypropylene fabric with anti-UV and grip treatment. Abrasion and tread resistant. Absorbs mechanical stress (tensile, shearing stress).

Top layer: heavy non-woven polypropylene fabric with anti-UV and grip treatment. Abrasion and tread resistant. Absorbs mechanical stress (tensile, shearing stress).

Reinforcement: waterproof, highly breathable microporous polypropylene film with anti-UV treatment.

Bottom layer: light non-woven polypropylene fabric

with anti-UV and grip treatment. Withstands abrasion of wooden support. Contributes towards the mechanical strength of the entire product.

ULTRASONIC LAMINATION

The three layers are spot welded together to ensure greater mechanical strength and breathability.

The three layers are spot welded together to ensure greater mechanical strength and breathability.